- An unparalleled commitment to quality!

- +91-9315902761

- sc@afpl.in

Range of Steels

Range of Steels

While AFPL has the infrastructure & capability to forge almost any raw material, we specialize in forging Super Duplex steels and Exotic Nickel, Copper & Chromium based alloys of international quality, that require extensive forging experience & craftsmanship. These Super-alloys a.k.a high performance alloys have become the steel of choice for corrosion resistance and versatility.

Some of the Raw Materials Forged by us are :

Carbon steels (such as A-105, EN-8, EN-9)

Low temperature steels (such as A-350, LF-1 & LF-2)

Stainless steels (such as F-304, F-316, F-321 & F-347 series)

Low Alloy steels (such as A-182, F-1, F-5, F-9, F-11, F-22, F-91)

Duplex/Super Duplex steels (such as F-44, F-51, F-53, F-55, F-60)

Non-Ferrous Alloy steels such Brass, Cupro-Nickel (90/10, 80/20)

Exotic Nickel Based Alloy Steels:

Monel 400

Inconel (600,601,625 and above)

Incoloy (800, 800H/800HT and above)

Hastelloy (C-276)

Why use Forging?

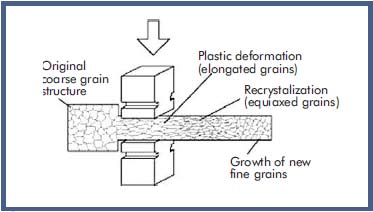

Forgings are grain oriented to shape for greater strength

In simple terms, forging is the process of forming and shaping metals through the use of hammering, pressing or rolling. Forging is often classified according to the temperature at which it is performed: ‘cold’ or ‘hot’ forging. Open die forging involves the shaping of heated metal parts between a top die attached to a ram and a bottom die attached to a hammer anvil or press bed.

Metal parts are worked above their re-crystallization temperatures ranging from 1900°F to 2400°F for steel and gradually shaped into the desired configuration through the skillful hammering or pressing of the work piece. The forging process has the ability to form the material to the desired component shape, while refining the cast structure of the ingot material, healing shrinkage voids, and improving the mechanical properties of the material. Forging also provides means for aligning the grain flow to best obtain desired directional strengths.

Secondary processing, such as Heat Treatment can also be used to further refine the part. Forged pieces are stronger than an equivalent casting or machined part. No other metalworking process can equal forging in its ability to develop the optimum combination of properties.

KEEP UP TO DATE

Information

Quick Links